Why use flex7 Lighting Distribution Boxes?

With over 55,000 flex7 Lighting Distribution Boxes installed every year there’s got to be a reason they’re such a popular choice. Every product in our vast range is carefully designed to ensure that it provides the best experience for the user. Our Lighting Distribution Boxes are by no means an exception:

High Quality Engineering

Externally, its tough anodised aluminium body makes our Lighting Distribution Box one of the most robust on the market. Internally, our unique patented contact system makes it the most electrically robust on the market. And as you’d expect from a quality product, all moulded components are V0 rated.

User-friendly design

The user-friendly design features a spacious wiring compartment which can be accessed by removing a single captive screw. In-line terminals are clearly labelled, and can accept 3 x 2.5mm², 2 x 4mm² or 1 x 6mm² conductors. Multiple cable entry points offer flexibility when installing. 2 steel snap-fit mounting clips make securing the lighting distribution box quick and easy, and ensure compliancy with IET wiring regulation 521.10.202.

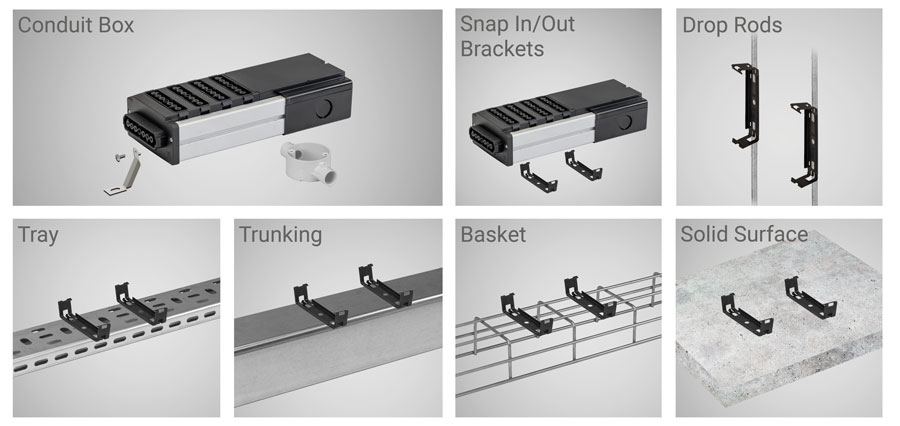

Multiple free of charge fixing options:

Every flex7 Lighting Distribution Box is supplied with 2 x steel mounting clips, 2 x M5 machine screws with lock nuts for mounting to trunking, cable tray etc. A supporting end bracket and fixing screw are also supplied for mounting the Lighting Distribution Box’s wiring compartment onto a standard conduit/BESA box.

Designed and manufactured in the UK

Flex7 Lighting Distribution Boxes are both designed and fully manufactured in the UK. This means that you’ll never have supply issues, waiting for our products to be shipped in from abroad.

7-pole – one size fits all

Our Lighting Distribution Box was the first and original 7-pole box on the market. This means the same product can be used whether the control you’re looking for is a traditionally hard-wired 230V, 1-way wall switch or you need to deliver power and DALI from a centralised headend lighting control system. If necessary, flex7 Lighting Distribution Boxes can even be used with other manufacturers’ control devices.

Modular flexibility

Each type of Lighting Distribution Box is available with 2, 4, 6, 8, 10 or 12 outlets. All boxes have an additional outlet on one end. If the unexpected happens and you suddenly need extra capacity, then this socket outlet really comes into its own. Simply plug-in a Flex7 Expansion Box to instantly add up to 12 extra outlets.

You may wish to power a separate group of luminaires. To do this, simply plug-in a Flex7 Tap-off Box. The Tap-off Box borrows power from the initial lighting distribution box, but creates an entirely independent group, which can be controlled separately.

If you want to put some distance between boxes rather than plugging them directly into one another, use one of flex7’s many prewired Expansion or Tap-Off leads

Boxes have a total rating of 16A so there’s plenty of scope for reducing your on-site terminations to an absolute minimum and in turn speeding up the installation.

Standards and testing: BS 5733 and UL 94 V-O

At the very core of its design our Lighting Distribution Box fulfils the requirements of BS 5733. It’s a longstanding, onerous British Standard written to ensure devices are able to withstand the day to day rigours they’re subjected to. Connection/disconnection under load is just one of the many mandatory tests. Not all connector systems in the world of commercial lighting are in compliance with BS 5733. Some of the standards used specifically require the manufacturer’s literature to clearly state the finished product is “intended for connection and disconnection without load, only”.

The material we use to make the moulded components in our lighting distribution box centres on safety; they’re free of halogens and in accordance with UL 94 V-0. The absence of halogens, just as with Low Smoke Halogen Free cables, means toxic gases are not produced in the event of a fire. For a material to be compliant to UL 94 V-0 it must, when tested in line with the UL 94 vertical flame test, self-extinguish within 10 seconds of the heat source being removed and not produce flaming droplets that could set secondary fires.

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk