What is CPR?

Europe’s Construction Product Regulation, commonly referred to as CPR, is a framework of 7 umbrella categories that seek to set out the basic requirements for construction products and processes employed throughout all EU member states.

CPR compliancy for many cables used in construction is now mandatory here in the UK. The directive requires the cable manufacturer to state, in line with BS EN 50575:2014, the way a product will react to, and with, fire. A Declaration of Performance (DoP) must be produced by the manufacturer for every product by way of supporting their claims.

Although there are some exceptions, generally speaking it is illegal to install any cable that was placed on the market on or after 1st July 2017 that is not CPR compliant.

CPR Classes

BS EN 50575:2014 sets out the requirements that allow a cable to be tested and subsequently entered into 1 of 7 classes:

| ACA | No reaction | |

| B1CA | Very low reaction | Non-flame propagator. Non-fire propagator (1.75m). Very low heat emission. |

| B2CA | Low reaction | Non-flame propagator. Non-fire propagator (1.5m). Low heat emission. |

| CCA | Reduced reaction | Non-flame propagator. Non-fire propagator(2m). Reduced heat emission. |

| DCA | Improved reaction | Non-flame propagator. Improved heat emission. |

| ECA | Basic reaction | Non-flame propagator. |

| FCA | Undetermined |

Cables meeting the criteria for class ACA have no reaction to fire i.e. they emit no smoke or toxins and will not contribute to a fire’s spread in any way.

At the other end of the spectrum are those in class FCA whose reaction to fire is ‘Undetermined’. Products in this class have undergone the minimum required for CPR compliancy. All that is verified is that the vertical flame spread, when tested in line with EN 60332-1-2, is >425mm. Everything else, such as whether it’s combustible, whether its sheathing/insulation will melt and start additional fires, whether it will emit toxic gas and thick black smoke is, as far as CPR is concerned, completely unknown.

A class ECA product fairs slightly better; flame spread is ≤425mm and as such is deemed to be non-flame propagating.

The test regime for DCA and above is more exhaustive. Data relating to a cable’s propensity to start additional fires due to droplets of molten material being formed, the heat generated and smoke & toxic gas emissions are included. Generally, these bi-products produced in the burning process reduce as one ascends through the classes.

It should be noted that the necessary performance threshold set for DCA classed products is some distance below that of CCA variants and above.

CPR assessment system

There are 3 verification processes that are employed when testing cables for CPR compliancy. The one used will depend on which class the manufacturer is hoping to achieve for their product. These 3 systems are called the Assessment and Verification of Constancy of Performance; AVCP for short.

System 4 – applies only to class FCA and simply requires the manufacturer to produce a supporting Declaration of Performance. The lack of any kind of mandatory or 3rd party testing limits the DoP to merely stating that the product’s reaction to fire is ‘Undetermined’.

System 3 – is used to verify products that will fall into ECA and DCA classes and includes the compulsory involvement of a 3rd party. A Notified Laboratory must be used to carry out the appropriate tests and is permitted to provide a classification report, but cannot issue a Certificate of Constancy Performance.

Despite a 3rd party carrying out the test, the manufacturer is allowed to select the test samples, meaning the potential to provide a ‘golden sample’ for the test process exists. Another limitation of System 3 verification is that a product is tested just once and is subject to no further testing in the future.

System 1+ – is the gold standard and is applied to the remaining classes; CCA to ACA inclusive. 3rd party involvement must be via Notified Body (eg. BASEC or similar) which, unlike a Notified Laboratory, is permitted to issue a Certificate of Constancy Performance.

Samples subjected to System 1+ verification must be hand-picked by the Notified Body, not the manufacturer, therefore the risk of a ‘golden sample’ being provided is zero. Finally, a product that falls within the scope of System 1+ is re-tested every 3 years ensuring its CPR classification and compliancy is continually proven.

Be sure a product is CPR compliant

If at all in doubt ask to see the relevant DoP. Although there is no legal requirement to do so, there should be no good reason for a supplier not to make it available on request.

flex7 & CPR

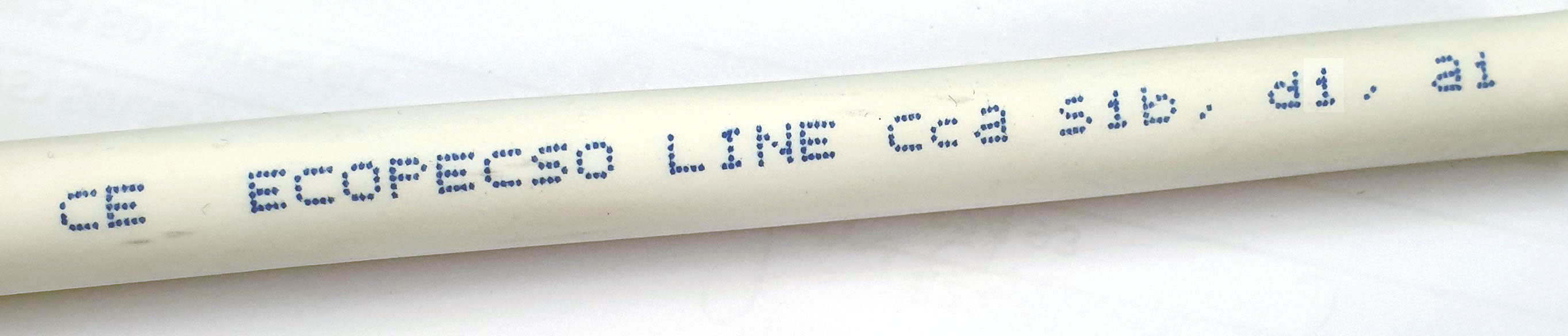

We believe that CPR class CCA is destined to become the benchmark for many commercial installations in the UK. It provides the benefits of reduced reaction to fire in tandem with the robust verification process of System 1+. As a result, we’ve made CCA the default offering with respect to all of our mains rated Low Smoke Halogen Free (LSHF) prewired lighting connection and lighting control products. This means that specifiers, installers and stockists can be confident that it will be suitable for a wide variety of applications as standard.

You can read about CPR in more detail here:

Or follow these links to BASEC’s website:

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk

Leave A Comment