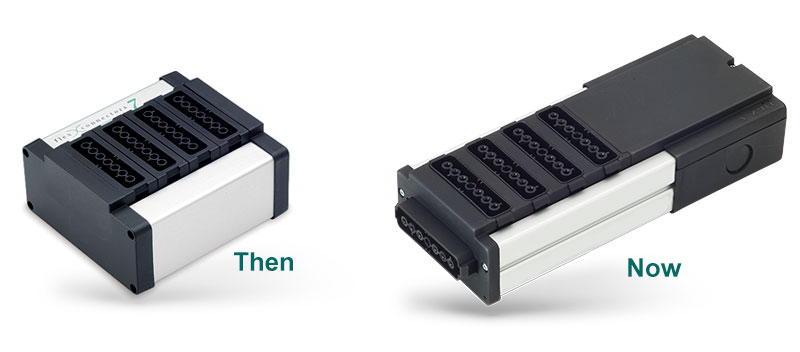

In 1998 flex7 created the world’s first 7-pole lighting connection interface. Since then we’ve designed an entire connection & control system around these clever plug & socket modules and although I could spend the next few hours waxing lyrical about all the innovative products flex7 has introduced to the commercial lighting sector in the intervening 20 years, I will resist the urge and instead focus on the heart of our product range; our lighting distribution unit or, as we prefer, connection unit. Designed to minimise the labour content of commercial luminaire installation, this was the first product out of the flex7 stable to incorporate our unique interface and was very quickly adopted by the industry. A comprehensive redesign in 2011 allowed us to turn a pretty good product into the excellent one it is today and make it first choice for many electrical consultants and contractors the length and breadth of the UK and Ireland.

Quality front & centre

The first thing to say is that both mechanically and electrically it is the most robust product in its class. The aluminium extruded body gives it the strength required to withstand the rigours of installation whilst the patented internal contact system means any risk of high resistive ‘weak’ points are, unlike alternative connection unit designs, entirely eliminated, ensuring years of uninterrupted service. Furthermore, should the unit be exposed to fire you can be assured that all non-metallic parts are made from a flame retardant, self extinguishing, halogen free material; PA6 UL96 V0 rated to be precise. Put simply, the plastic cannot sustain its own flame and, in the event it is subjected to fire, will not produce halogenated gas emissions; the type that play a significant part in so many building fire fatalities.

Time’s money

Installing the connection unit couldn’t be simpler. Two very strong, spring steel clips are supplied with every unit. A single central fixing is all that’s required for each; plug & screw, nut & bolt, wedge anchor, Hilti (type) fixing etc. – your call. Once they’re attached to the building fabric or containment the unit simply snaps into place. The clips have a grip any self respecting crocodile would be proud of, holding the connection unit securely in place and crucially, because they’re metal, allow full compliance with 521.11.201 of the IET Wiring Regulations, 17th Edition, or 521.10.202 for those of you already conversant with the recently released 18th Edition. Finally on the subject of fixing, the unit can be quickly released from its clips should repositioning be necessary at some point in the future; no more struggling with damaged, rusty screw heads while stretching into the ceiling void.

Connecting the fixed wiring is also a breeze. Just one screw secures the slide-off terminal cover and there are multiple 20mmØ and a 25mmØ knockout to accept conduit adaptors or cable glands of any variety. Once inside there’s bags of space to allow neat routing of the wiring to the strong, cage clamp terminals, each of which easily accept 3 x 2.50mm2 conductors. Regardless of variant, every flex7 connection unit has 2 x earth terminals in order to allow compliance with 543.7.1.204 of the IET Wiring Regulations, 17th & 18th Editions, when the need arises. And continuing with the ‘what you get as standard’ theme, all of our connection units contain 7 x contacts which means that even if you’re only installing on/off luminaires to start with there’s always an upgrade path to regulating (dimmable) luminaires or products with more complex control requirements if things happen to change in the future.

flex7 starter units:

In addition to these three ‘Starter’ units are two other variants, ‘Expansion’ and ‘Tap-off’, both constructed using the same interface, materials and principles that can be used to extend a lighting circuit into other areas or rooms without the need for further on-site cable prep. and terminations.

In addition to these three ‘Starter’ units are two other variants, ‘Expansion’ and ‘Tap-off’

Every flex7 connection unit is available with 2, 4, 6, 8, 10 or 12 outlets and can accept traditional hard-wired control (an everyday 230V switch for example) directly into its terminals. However, if speed of installation is the goal then the best option is to use flex7 plug-in controls which are fully modular, operate at PELV and require no on-site terminations whatsoever as all our sensors and switches benefit from RJ connectivity and only need to be plugged in; it quite literally takes seconds. If a project calls for an addressable ‘front end’ system, then our units can handle that too as there are always enough terminals and contacts to cater for both power and data signals / DALI. In short, when it comes to controlling luminaires, flex7 connection units are ideal for the very simple to the very complex and anywhere in between.

Finally, being just one component of the whole system guarantees that there are literally 1,000’s of off the shelf, compatible pre-wired leads and control devices that can be used in conjunction with these connection units. All designed to simply plug-in, meaning that regardless of complexity, as long as the Live Neutral & Earth are in the correct terminals, there’s nothing else to worry about; flex7 can deal with all the other time consuming terminations.

So to summarise, connection units from flex7 are:

More On The Author

Paul Bellamy has been involved in the electrical industry all his working life, initially in contracting, before moving into manufacturing. With his wide range of industry knowledge amassed over 36 years, he is now Managing Director of flex7. Paul has been with the company since its early years and is the brains behind some of flex7’s most innovative products.

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk

| Call Us: +44 (0)20 8580 1066 | sales@flex7.co.uk

Leave A Comment